To dissolve the logs on the boards at home is quite problematic, since not everyone has the opportunity to purchase a complete sawmill for these purposes. However, you can use an alternative option - to make a home-made manual sawmill based on an electric chain saw.

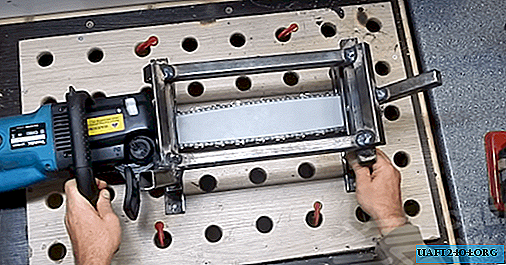

The design of the mini-sawmill is quite compact and simple. Of the basic materials for the implementation of this idea will be required: sections of profile pipes, steel corners, long studs and bolts with nuts, as well as the chain saw itself. Performance is not high, but for home use it will do.

Design features of a hand saw

The sawmill frame is welded from profile pipes of square section and equal-angle corners with sides 35x35 mm. From the outside in the upper part there are two handles from the profile to hold the sawmill during the sawing of the log.

Also, this design can be fixed on the table permanently. The supporting part of the frame is made of steel corners 35x35 mm, and in one of them a small cutout is made by the grinder so that the chain tension can be adjusted without problems.

The upper and lower parts of the structure are interconnected by M10 pins. The chain saw tire is attached to two profiles that can be moved in height, thereby adjusting the thickness of the board during the sawing process. Thus, a manual sawmill from a chain saw is quite versatile.

If you use the sawmill in the manual "mode", then first the log itself is attached to the table surface, to which the guide rail from a flat board is screwed, and then the sawmill rests on it. When using this design, it is stationary - on the contrary, the sawmill is first attached to the workbench.