Do you want to make a neat metal grate without using a welding machine, and therefore without additional work on cleaning the welds? Well, it is quite possible. To assemble the grate without welding, you will need to make a small device - a simple punching mechanism.

With this homemade product it will be possible to punch square holes in the profile pipe and insert metal square rods into them. Although, perhaps, this adapt is useful not only for metal structures.

The main stages of work

The device is very simple, consists of two parts. The first part is made of a tap (its size may be different, depending on what size of the hole is needed).

We grind the tap from the sides to a length of about 45 mm, forming a rectangular part (in our case, the size is 12x12 mm). And we end off the butt at a slight slope - about 15 degrees. The item is ready.

The second part is milled in two parts. In two sections of the 16th strip, a length of 5 cm, grooves are made, then both parts are welded together. The width of the part should be 30 mm.

Further, from the other end, the part is milled to the size of the profile pipe, in which holes will be punched. To fix the inserted pipe with bolts, we drill two holes on the sides.

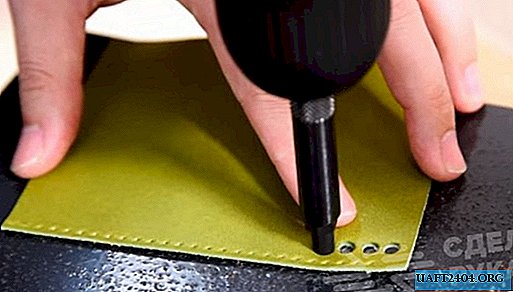

The home-made device is completely ready, and you can begin to work. We lay the profile pipe on a solid metal surface, attach our structure from above, tighten the pipe with bolts, using the key.

Let's make a marking, so that then we can pierce it exactly from the opposite side, if a through hole is needed. Insert the punch and hit with a hammer. Then we turn it 180 degrees. and continue to knock out the square hole. Thus, you can quickly and easily make holes and weave the grate!