For a true master, any trimming of building materials is not a waste of production, but valuable and most importantly - free "raw materials" for various homemade products.

From a pile of rubbish, you can create original masterpieces that not only act as decor, but can also be useful in home life. A table lamp made of polypropylene pipe can be used both in the room, and in the workshop or garage.

To make this design with your own hands, it is not necessary to be a plumber or a turner, but it is advisable to have some experience in electrics. If you never picked up a soldering iron and did not work with heat shrink, be careful with this project.

The main stages of work

The design of the table lamp itself is assembled from polypropylene fittings and pipe scraps. All necessary materials for work can be purchased at a hardware store or use the remnants of pipes and fittings after repair.

The first step is to cut a small piece of polypropylene pipe and drill a hole in the center for the on / off button.

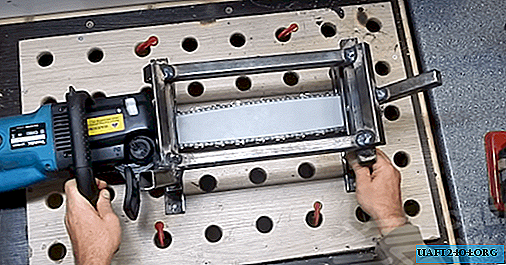

In the tee, you need to drill a hole for the cord that will connect to the cartridge. After that, you can begin to solder the main structural elements using a welding iron for PP pipes.

At the last stage, the final assembly of the lamp and the soldering of wires are performed. Details on how to make a table lamp from a polypropylene pipe with your own hands can be found in the video on the website.