Share

Pin

Tweet

Send

Share

Send

Many homemade manufacturers have long used compressors from refrigerators as air. Connect them to the receivers, inflate the tires of cars, use a spray gun, etc. It’s only a shame that the compressor motor works from a 220 V mains voltage and that a mobile installation cannot be made from it. Or is it still possible? Let's try.

12V car compressor from the compressor of the refrigerator

We disassemble the compressor housing. To do this, using the angle grinder, cut off the top cover. And extract the contents from the bottom bowl.

We release the remains of freon by rotating the motor shaft manually.

We unscrew the four screws securing the stator.

We remove the stator with windings, we will no longer need it. We will not touch the rotor - it will serve as a flywheel.

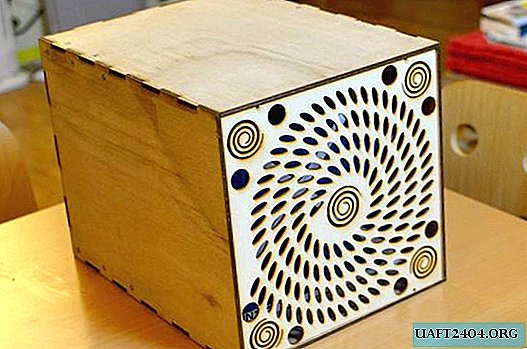

Prepare the base from a rectangular piece of thick chipboard.

Paint with spray paint, ennoble the edges with decorative overlays.

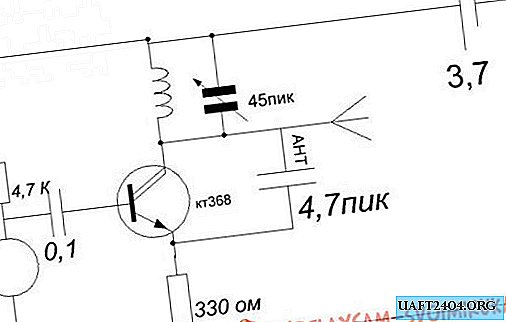

For rotation will use a DC motor at a voltage of 12 V.

From a sheet of thick steel we make fasteners or find similar ones from among the purchased ones.

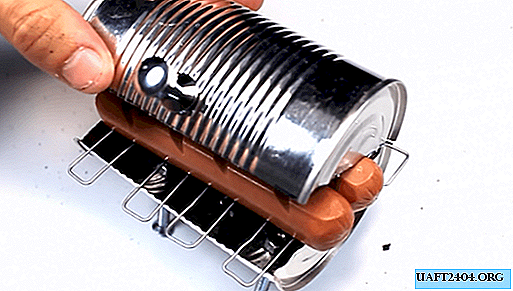

We attach the compressor to the base with these mounts.

Opposite the compressor, we attach the motor so that the shafts are at most in the same plane opposite each other. Connect them with a piece of watering hose and fix with clamps.

Add a power switch.

Check, connect to the battery 12 V.

The engine rotates the piston compressor shaft without any problems.

Below, on hot glue, made of heat-insulating material, add three strips - these will be anti-vibration legs.

We attach a hose with a nozzle for pumping automobile wheels to the output tube.

Check in action. We inflate any tires, both motorcycle and bicycle, and automobile.

Of course, there is no need to wait for space recoil after replacing the motor. The compressor has significantly lost in power, but still copes with its duties completely and completely, although for a longer period of time.

Share

Pin

Tweet

Send

Share

Send