During summer cottages, you often have to cut shrubs, remove weeds, cut grass and perform other operations with garden scissors. This hand tool can be bought in a store or made independently.

Many summer residents choose the second option, since the design of garden shears is very simple and you can make them yourself from improvised materials. Since the tool has a slightly elongated shape of cutting knives and handles, compared with a pruner or conventional scissors, workpieces of suitable sizes will be required.

Manufacturing process

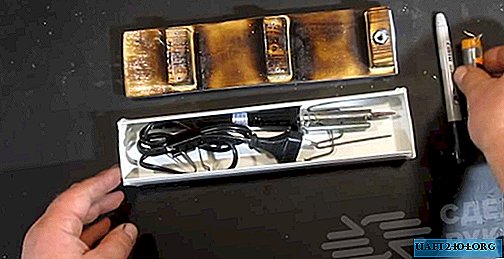

As the main "building materials" for this homemade product, it will be necessary to use two steel plates and two rods of circular cross section, as well as a bolt with a nut for connecting parts. From the tool you will need a grinder, a welding machine and a device with which you can bend pipes and fittings.

In steel plates, at a distance of about 2-3 cm from the edge, we drill one through hole, after which we weld round bars to the workpieces (it is better to use the bars, not the reinforcement, since the first ones have a smooth surface).

Then the edges of the handles need to be slightly bent on a bending machine to make it more convenient to hold them, and on the plates using a grinder to make a cutting edge. Next, the two halves of the scissors with the edges cut off at an angle are connected by a bolt to a nut.

After that, the tool needs to be cleaned well, if necessary, sanded and painted, and you can work! Home-made garden scissors are no worse than factory ones, but they cost almost a penny, since they are made using affordable materials.