Using this homemade nozzle on the angle grinder it is very convenient to grind surfaces or metal parts that are in hard to reach places. The grinding nozzle on the rollers for the grinder will be useful in the process of cleaning welds, removing rust, and also when you need to grind or polish various surfaces "dry" (that is, without cooling).

Please note that for more comfortable work it is more advisable to use angle grinder, which provides the ability to adjust the speed. The main advantage of this nozzle is that it is quick-detachable - thanks to a well-thought-out design, the installation and dismantling process takes no more than 10-15 seconds.

We make a grinding nozzle on casters

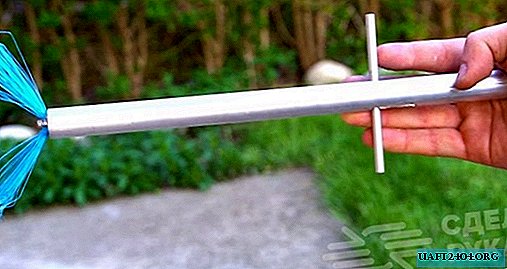

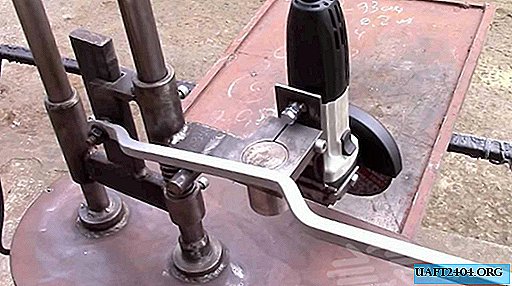

The homemade construction of the nozzle for angle grinders consists of three rollers (one of them is adjustable), as well as a special fastening system, thanks to which quick installation and dismantling is provided. And since we will use factory castors, the main work is related to the manufacture of the main fastening elements.

From sheet metal, it is necessary to cut an elongated trapezoidal blank in which we drill a round hole with "spikes" for installation on a seat in the gear housing. Next, make markings on a steel sheet and cut out another workpiece, which we connect with the previous part. The main part of the grinding nozzle is ready.

A nut of a suitable diameter must be pressed into the hole of the central roller, which will be screwed onto the gearbox shaft. At the last stage of work, we make the rest of the "components", after which we assemble the entire structure together, install the finished grinding nozzle on the angle grinder, stretch the strip of sandpaper and you can get to work.