In home workshops, where there is no place for installing stationary bending machines, it is more advisable to use hand tools that are more compact in size.

To bend steel sheets in this case, a rotary mechanism with a traverse is used. The workpiece is clamped between two planes and, with the help of a movable part with handles, bends at the right angle without any additional devices.

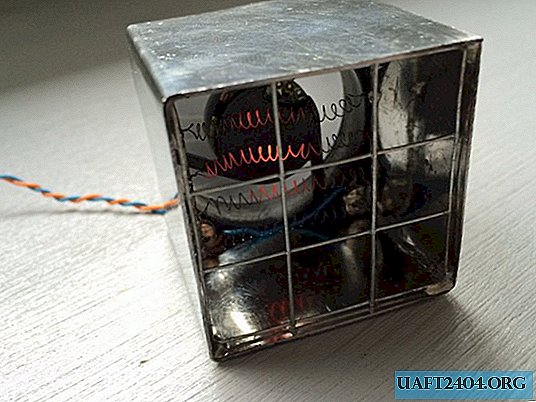

To make the bending machine an improved design, you will need steel corners of suitable length, as well as hinges, metal strips, studs and fasteners. Handles are made of square shaped pipe.

The process of manufacturing a manual bending machine

Two corners are interconnected by external sides with the help of hinges - you can choose factory sizes or grind them on a lathe. To weld the loops to the corners, it is necessary to make cuts along the edges of the corners.

In the third corner, you need to drill holes, insert metal threaded bushings into them, and then weld along the contour. Then, handles in the form of a U-shaped frame are made from profile pipes and welded to the movable part of the bending machine. The working elements of the bending machine are connected to each other by means of bolts with nuts.

Last of all, it is necessary to make additional stiffeners from pieces of thin steel strip and thrust studs - they add strength to the entire structure and are needed so that the corners do not deform during the bending process.

The obvious advantage of the improved design of the manual bending machine is its relatively simple manufacturing technology and high productivity (when using steel sheets of small thickness).