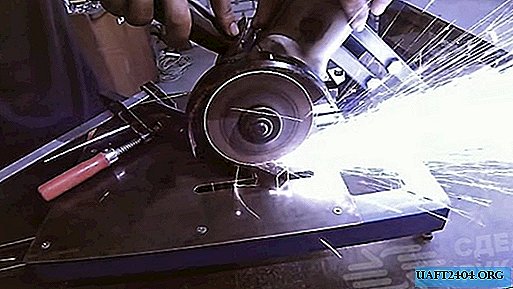

Using an angle grinder in the workshop, you can perform a variety of operations, from cutting metal blanks to grinding parts.

However, the capabilities of the grinder can be expanded using simple home-made devices - for example, a table stand-rack to cut workpieces at an angle of 90 degrees.

For the manufacture of this device you will need affordable, and most importantly - inexpensive materials that are always at hand. Structurally, the platform is a platform that is attached to the table, and a vertical rack with a movable mount for the grinder.

The main stages of work

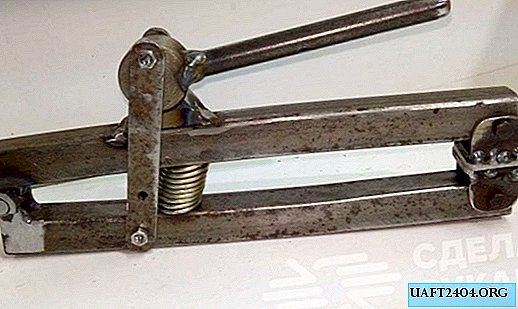

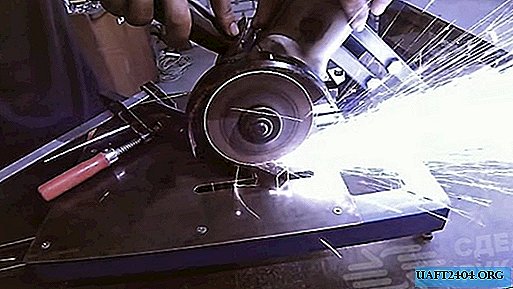

First of all, it is necessary to cut four corners 32x32 mm: two - 30 cm each and two - 40 cm each. We cut the corners with a grinder at 45 degrees. Then we weld a rectangular frame from the corner pieces. To do this, you can use the corner clamp (factory or homemade).

Next, two segments of the profile pipe with side dimensions of 20x20 mm need to be welded to the inside of the welded frame - there should be a small gap between them. On top we fasten two sheets of metal. The result is a solid base for the upright.

At the next stage of work, we make the mount for angle grinders from a piece of sheet metal with a thickness of about 2-2.5 mm, which must be bent in a vice with the letter "P". Mounting holes are drilled at the edges of the plate. The standard handle is twisted on one side of the gear housing, and the M10 bolt on the other.

Assembly assembly

A profile pipe is welded to the plate, bent at a slight angle at the end, and two more sections of the profile are attached perpendicularly to it. You need to weld an M12 stud to a large washer. A corner with a plate 100 mm long is welded to a steel pipe cut along.

We insert a hairpin with a washer into the pipe, on which two bearings are mounted. We attach the carriage to the base, and to it is a home-made mount for the grinder. Drill holes for adjusting screws in the upright post.

Then, an emphasis is made from a corner and a steel plate 3 mm thick with a clamping bar, which is fixed with bolts with wing nuts. For a more aesthetic look, the assembled platform-rack for angle grinders can be painted.