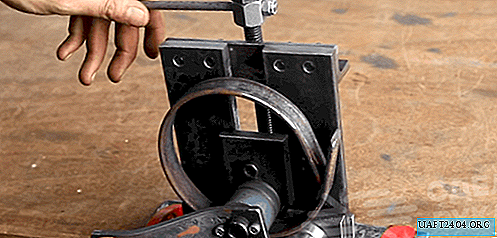

A simple do-it-yourself roller ring bending machine allows you to bend metal strips of different thicknesses into rings of the desired diameter, which can be used, for example, for making oak barrels, as elements of artistic forging, and also for other purposes.

To make a roller ring bending machine for a home workshop, you will need metal plates about 1-2 cm thick, bearings, a steel roller, angle sections, as well as an adjusting screw and fasteners.

The main stages of work

First of all, we cut off three plates of the required length, mark and drill holes in them, and then with the help of two bolts we fasten four bearings on top.

The lower plates must be screwed to a piece of steel corner, which will be attached to the table or workbench using clamps.

On the reverse side two more corners are attached (one fixed - in the upper part, the second - moves in a vertical plane). Through corners, through holes are drilled into which a screw is inserted. A guide nut for the screw is welded to the upper corner.

At the end of the screw, you need to drill a hole, tighten the nut, and make a small screw. A steel roller is attached to the movable plate, which will be adjustable in height. Whereas the lower rollers are fixed.

Here is such a simple design. For a detailed assembly process of a homemade roller ring bending machine, see the video on our website. Write in the comments, did you like this homemade product?