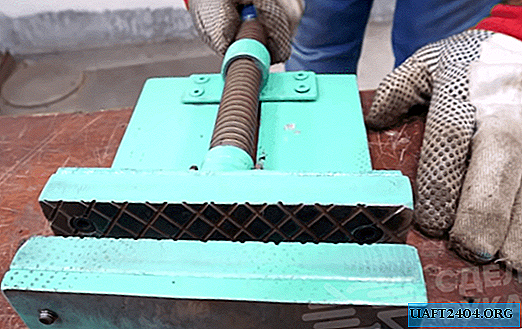

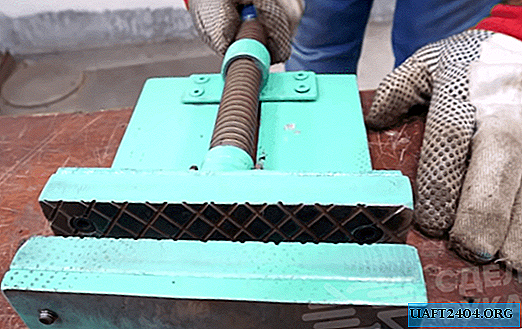

Not all models of bench drilling machines are available complete with a vice. Often they have to be bought separately. However, since factory vices are not cheap, it is easier and more profitable to make them with your own hands if you have materials. Moreover, they will be as strong and reliable as purchased.

Powerful vice for working on a drilling machine can be made of thick metal (at least 10 mm). Thanks to the massive design, they will ensure reliable fixation of the workpieces, which will allow you to drill holes with maximum accuracy.

The main stages of work

First, cut off two thick rectangular plates that will be used to make a vise bed. We expose a gap between them, and then we weld another metal plate on one side, setting it perpendicular to the base.

After that, cut the size of a piece of steel corner and drill two through holes in the lower shelf. It will also be necessary to cut a small piece of rectangular shape out of metal, which will pass in the gap between the bed plates. A corner is attached to it.

On the edge of the vise bed we install a guide for the screw. To do this, four holes are drilled in the plates for fixing bolts (for the bolts, it is necessary to cut the thread). "Pyatak" on the screw is welded to the corner shelf.

Then it remains only to make and fix the clamping jaws of a vice. Before assembly, all parts must be sanded and painted. For more information on how to make powerful thick metal vice for working on a drilling machine, see the video on our website.