Keyless clamps save time when performing large volumes of work. And it is not necessary to buy these clamps in the store - you can make them yourself from improvised materials.

The home-made quick-clamping clamp, which was made by the author, will be especially useful when processing a large number of workpieces of the same thickness. It is only necessary to set the size, and then the fixing of details to the table will occur on the "machine".

For the manufacture of a universal quick-clamp clamp, a steel strip of 5 * 30 mm and a bolt with an extended M14 nut will be required.

You will also need four bolts of a smaller diameter for a hex wrench, nuts with a nylon insert (used instead of engravers), a bolt with a nut - size M8, and an enlarged metal washer.

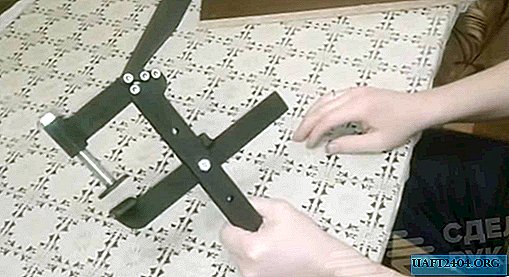

The main stages of work

The first step is to cut pieces of different lengths from the steel strip: 2 pieces 300 mm long, one piece 250 mm long and three more small pieces.

Further, from the cut blanks and previously harvested parts, it will be necessary to assemble the main structural elements.

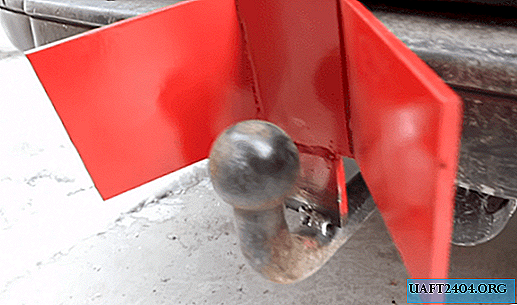

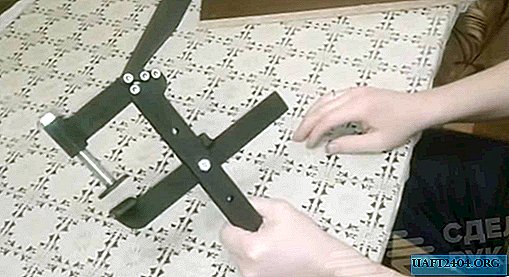

After that, you can start grinding and painting parts, and their subsequent assembly. Conventionally, the clamp consists of four nodes: frames with holes, strips with a clamping sponge, handles and strips with an elongated nut welded to it.

A stud with a clamping nickel from an enlarged metal washer is screwed into the nut. For a detailed process of manufacturing a universal quick-clamp clamp with your own hands, see this video.