Share

Pin

Tweet

Send

Share

Send

What to prepare

The device itself is made of a small section of timber, preferably from maple, wood has great strength and at the same time low coefficient of friction, which facilitates the sliding of the workpiece during rotation. Turning is done with a chisel, the workpiece rotates with a drill. For manufacturing, you should have drills with a diameter of 10 mm and 12 and electric sharpeners for chisels. If they are not, then you can bring the tool manually.

Tool manufacturing process

Dowels are made from wooden blanks. First, cut a square on the lathe with a side 1-2 mm larger than the diameter of the dowel, then carefully remove its edges.

If possible, smooth the corners using a table router. In our case, the diameter of the finished dowels is 10 mm, respectively, the side of the square is 12 mm. At the output, workpieces with a cross-section close to round are obtained.

The device has several holes, each allows you to produce dowels of a certain diameter. For each type of dowels, a hole is made with two diameters - the larger corresponds to the dimensions of the workpieces (in our case 12 mm) and the smaller corresponding to the diameter of the dowel (in our case 10 mm).

Drill a hole with a diameter of 12 mm to a depth of about 2/3 of the width of the bar. To control the depth, install a stop on the machine.

Insert a drill with a diameter of 10 mm into the chuck and drill a hole to the end.

Make a flat platform for installing a chisel. For the entire length of the hole with a diameter of 12, a part of the bar for removing the chisel is removed. Using a vernier caliper, measure the distance of the hole from the edge of the workpiece and, taking this parameter into account, set the circular saw.

Carefully cut the saw into the workpiece; the cut length must not reach the section with a smaller diameter. This hole should be solid and hold the workpiece all the way around.

Check the results of sawing, with a chisel, remove the extra piece of wood.

If during the cutting it was not possible to comply with the recommended accuracy and the smaller hole is also touched, then the device should not be thrown away, it will work, only the diameter of the dowel will slightly decrease. For carpentry, this is not critical.

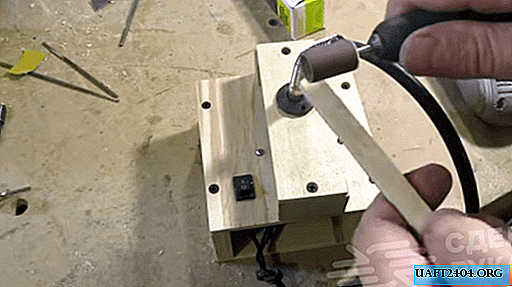

Only a perfectly sharp chisel can sharpen a tree. Carefully sharpen it on a special grinder. Then bring the GOI paste to perfect condition.

Clamp the chisel on the fixture and manually rotate the workpiece several times. Check cutting depth and rotation force. Adjust the cutting parameters if necessary. If they need to be enlarged, then deepen the platform a little on the circular machine.

If the chisel drops very low, then lift it with various pads. You can use ordinary paper.

With a clamp, fix the position of the chisel, clamp the fixture in a vise and you can begin to manufacture dowels.

Workpieces are clamped into drills, cutting modes (revolutions, feed and depth) are determined empirically.

Conclusion

Most of the chucks are designed for a maximum drill diameter of 10 mm, workpiece Ø 12 mm is no longer included. To eliminate the problem, manually grind 2-3 cm of the workpiece and then clamp it in drills. It is recommended to prepare several devices, which will make it possible not only to make dowels of various diameters, but also to use beautiful round elements for decorative purposes.

Share

Pin

Tweet

Send

Share

Send