Share

Pin

Tweet

Send

Share

Send

Eternal tools do not exist, even the highest quality fail. This is due only to mechanical damage during operation, but also to metal fatigue. Even under normal operating conditions, microcracks appear in it, which then increase to critical sizes. Replacement is also required for bearing wear. The most loaded tool element is the lower gear.

Instruments

You will need a set of heads and a narrow flat screwdriver. The size of the wrenches depends on the manufacturer of the trimmer, and the screwdriver must go into the technological hole located at the bottom of the gear case.

Replacement process

First, the reel with fishing line should be disconnected from the gearbox. It is screwed onto the threaded portion of the gear mechanism. Tightened by hand, and then clamped under the influence of inertia during oblique operation. This means that there is no need to use any devices to unscrew.

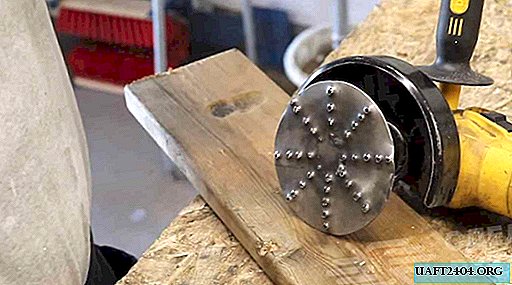

Insert a flat screwdriver into the special technological hole, slowly scroll the coil until its end falls into the recess of the slots.

Firmly hold the screwdriver in one position with one hand, and unscrew the part in the opposite direction of rotation with the other. There are gearboxes with a special through hole for disassembly, it is easier to change them.

The gear to the rod is attached with two bolts. One fixes it in the center, and the second clamps and does not allow displacements during operation.

Unscrew the centering bolt and remove it from the rod.

Loosen the clamping bolt two to three turns. Remove the lower gear, it will come off much easier if you constantly turn the case in different directions.

Using the same algorithm, reinsert the new one, align the holes in the body and the rod. Insert the appropriate bolt, then tighten both hardware on the gear housing until it stops.

Put a flange on the shaft splines to drive the coil, tighten it. The flange not only rotates the cutting element, but also protects the gearbox from dirt.

Conclusion

Before starting work, it is recommended to clean the parts from dirt, remove adhering grass from the bolt heads. The time spent on cleaning is much less than the further elimination of problems.

When buying a new part, keep in mind that each company produces its own gearboxes, in principle they do not differ in any way, but the sizes can be different. This is done on purpose, the goal is to force consumers to buy their products.

Share

Pin

Tweet

Send

Share

Send