Share

Pin

Tweet

Send

Share

Send

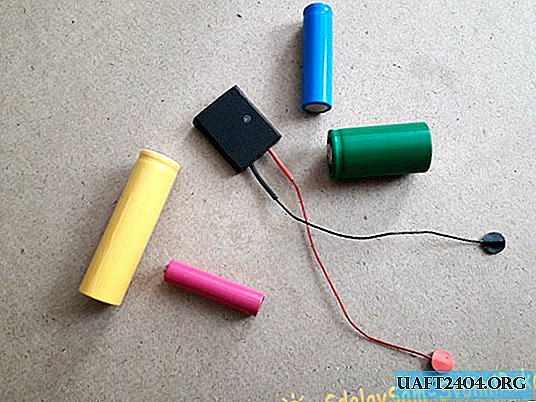

Sometimes it happens that you need to charge a battery of a certain size, but we have a charger for a different size. Chargers in stores a huge assortment, both for certain batteries, and universal, charging different batteries. It would seem that it could be easier: go and buy! But there is an option to get the required literally for a penny, and at the same time no less effective in work. A good universal charger for 3.7 volt batteries, of various shapes and sizes, costs at least 1000 rubles, but I want to offer an idea how to get the same in function, but costing 50-70 rubles. And at the same time compact, able to fit in a matchbox!

Will need

- Charge controller, for 3.7 V batteries. (with indication).

- A sheet of plastic, 1 mm thick, about 10 × 10 cm (this is with a margin!).

- Glue second.

- Stationery knife or technical scalpel.

- Scissors.

- Ruler.

- A piece of USB cable (or similar in thickness), see 7-10.

- Two wires, black and red, 10 cm each.

- Shrink tubes.

- Two neodymium magnets, approximately 8 × 8 × 1.

- Soldering iron with tin and flux.

- Bor machine, with a set of stones, drills and discs.

- Glue "cold welding".

- Colored self-adhesive film.

Making a universal charger for any size of batteries

The most important detail in this assembly, of course, is the charging module. I bought this module in a Chinese online store. The module has a Micro USB input, like in a phone, which can be connected via USB cable to any USB port. Two tinned contacts act as an exit; plus and minus, which are marked with the corresponding characters. The output has a constant voltage of 5 V and a power of 1 A.

I can say with confidence that these Chinese modules of a similar type are quite reliable (which is quite surprising, knowing about their origin!), Since I have been ordering and using them for quite some time and have never come across defective or broken ones. So, first you need to solder the output wires to the module - red, for plus, and black, for minus.

Now let's take care of the case for this module. To do this, you must first measure the module.

Then, we need plastic. I took the black one, but any one is possible, since it will still be closed in the end.

We transfer the parameters of the module to plastic, taking into account the margin for the end walls. 5 millimeters from each edge. Cut out.

Next, using a second glue, glue the module to one of the plates. Glue in such a way that the Micro USB connector is flush with the edge of the workpiece housing. Do not worry that with glue we can disrupt the module - there is nothing on the other side, you can safely glue it. And immediately, cutting off the pieces of cable of the appropriate length, glue them as end walls.

Why cable? Because cutting such thin strips of plastic is a very dreary task. And the cable has a round shape, and after appropriate processing with sandpaper, the ends of the case will also have a rounded shape. Next we need cold welding. Cut off a piece and, according to the instructions, wetting your hands with water, mix the components to a homogeneous mass.

Having obtained the desired consistency, you can put the finished glue aside for 15 minutes so that it becomes more elastic and not so soft. In the meantime, you can prepare the top case cover. To do this, we note the approximate location of the charging indicators under this part, and drill a 3 mm hole in this place. This is for visual observation of the charging process. So, the glue is a little hardened. Now we install heat pipes on the output wires, and we seat them with a lighter.

This is in order not to break the wires during further operation, as they will be movable. Now we fix the free ends with cold welding. Apply a second glue to the edges of the upper plate, and set it in place. Do not forget about the display hole - so that it is in place!

You can close this hole with a piece of light plastic. For this purpose I took a flash diffuser from a broken phone. He perfectly approached the hole, even glue was not needed!

Now we process long ends with sandpaper, those in which pieces of cable. Stitch corners. The end face is rounded.

We trim the excess cold welding that also appeared. Well, you can glue it with a film.

To give a more aesthetic appearance. You can not suffer, pasting each hole. I just pasted the entire surface with a film of the color I liked, heated it slightly with a lighter, so that the film settled more densely, and marked all the holes. Then he simply cut a hole with a technical scalpel under the Micro USB connector, and under the indicator.

Well, the end, from where the output wires stick out, can not be glued. It remains to solder the neodymium magnets to the contacts.

Here it is necessary to act extremely carefully, but at the same time and quickly. Solder the wires to the magnet very quickly so that the magnet is heated as little as possible. Otherwise, with prolonged heating, it will lose its magnetic properties, and all work will go down the drain. Well, after soldering, you can stick on the place of soldering markers of the corresponding colors, so that there is no confusion when connecting.

Although, if you mix up the contacts when charging, nothing bad will happen - the controller will simply give a blue signal on the indicator and after a while turn off the current supply. Here is such a compact charger turned out.

They can charge batteries of different sizes, but of the same voltage. Nothing terrible, of course, will happen if you connect a battery of, say, 1.2 volts to it. Just this battery does not "live" for a long time. Thus, this universal charger cost me 53 rubles, and about an hour of work. The benefit is obvious. And it charges, no worse than the device from the store.

Share

Pin

Tweet

Send

Share

Send