Share

Pin

Tweet

Send

Share

Send

Going on a long journey, fishing with an overnight stay, hunting, or just relaxing, many fishermen, hunters and tourists load a small chainsaw in the luggage of the car. Most often, this is a small delimber to cut a cracker into a supply of firewood. But what do lovers of hiking, long distances? You won’t put a chainsaw in your backpack, even if it’s a small one — it will simply supersede all the other accessories needed on foot. And the prospect of dragging extra weight, even if things are necessary in a campaign, does not cause much optimism. Of course, in a backpack there is always a place for a small hatchet, but there are times when you need a saw. For example, saw off a piece of a thick log that will burn all night. The dry, resinous trunk of a coniferous tree is unusually hard, and you can bale it with a small hatchet all night. No fire is needed! In this case, the chain from this chainsaw will help us out very much, from which we will make a pocket chain saw. With its help, you can quite easily and quickly saw through the trunk with a diameter of up to 20 centimeters. Making such a saw is half an hour. I, among other things, junk in the barn, lay a torn chain from a chainsaw, from which I made a pocket chain saw.

Of course, it can be made from a new chain, but, in my opinion, from a new chain the saw will not be so effective; it has too wide, not sharpened teeth and it is not developed - it will be harder to wield it. On the old chain, all the teeth are already usually thin and sharpened, which is very convenient for a saw of this type.

Will need

- Chainsaw chain (preferably old, already developed).

- Emery machine.

- File (round, thin, for sharpening teeth).

- Thick metal rings (from a bunch of keys, or from a key ring) 2 pcs.

- Tin and flux.

- A gas burner or a powerful lighter.

- A pair of links from a not too thick chain (as in the photo).

- Machine oil

Making a chain pocket saw:

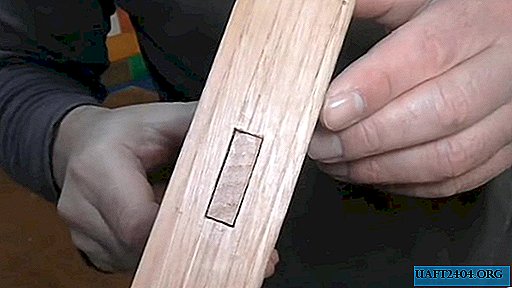

First, we’ll rid the chain of all the excess and sticking out. In addition to sawing teeth, of course.

Using an emery machine, grind or saw off all the protrusions, teeth for the sprocket and tire, and stops, which are located immediately behind the saw teeth. The result is such a chain:

Next, you need to give the desired shape to the saw teeth. Since we will work with a chainsaw in both directions, and not as it worked on a chainsaw - in one direction, then the teeth, respectively, must be sharpened from both ends. On the emery machine, with the help of a thin cutting disc we give the teeth a triangular shape.

Armed with a round file, or a thin file, we grind the teeth on the chain.

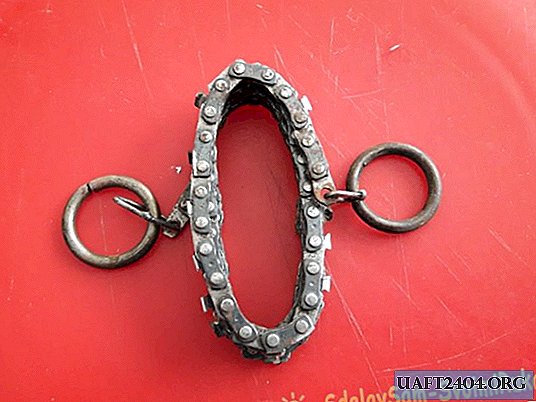

Now we need two powerful iron rings, as well as a couple of links from a small chain.

We expand the links a little so that the iron ring, worn later, fits freely in them.

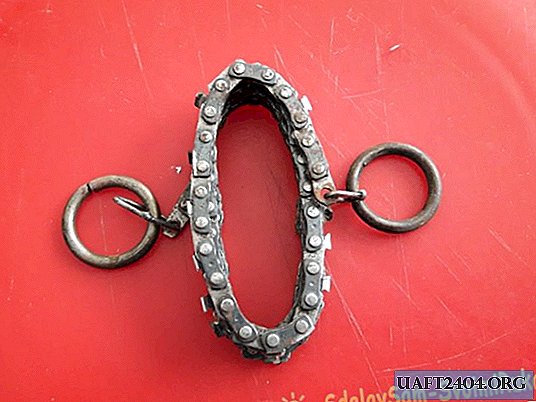

We connect the metal ring and the end of the chain with an extended link. It should look like this:

Next, let's take care of the handles. At first I didn’t guess a bit with the material for the handles; cut off 16 mm metal-plastic tubes in the width of his gear.

Why not guessed? Because I didn’t take into account that in winter, in the cold, plastic will slip out of woolen mittens, and it’s cold to work with gloves. So it is better to use instead of handles rough branches of suitable thickness cut in the same place, in place. Although it’s everyone’s business here - I personally (as can be seen on the video) managed only fine with metal rings attached to the ends of the saw chain, when I sent constantly slipping tubes to the fire ... so, after we connected all parts of the saw chain, it’s necessary to solder the closed ones the ends of metal rings and links, just in case. For greater reliability, so to speak. Warm the metal rings with a soldering iron for too long, therefore, I soldered them with a powerful lighter - I just cleaned the soldered surface of the metal with sandpaper, greased it with flux, warmed it with a lighter and applied tin. It remains only to lubricate the saw chain with machine oil.

I used gun oil for this, but for lack of one, you can use any. Though vegetable! That's all. It remains to conduct a test. As you can see in the video below, the chain does a fine job with a dry tree, even though I did not use the handles.

If you need to cut it down, which is more serious - cutting a couple of branches for the handles is never too late. With such a saw, you can easily cut firewood for the future, so that later, without saving, maintain fire for heating and cooking.

The most important and perhaps the biggest plus of this product is that it is very compact and lightweight. Fold the chain into rings, put in a bag, and put it in the pocket of a backpack or bag - a minute deal. Do not forget to lubricate the chain with oil, and file its teeth after every trip, and it will serve you for a long time, as well as any other thing with good care and a good, thrifty attitude.

Share

Pin

Tweet

Send

Share

Send