Share

Pin

Tweet

Send

Share

Send

-Sculptural clay (and straight arms).

- A board for modeling.

-Food silicone (silicone compound 1 liter).

- Injection plastic.

- Epoxy resin or varnish.

- Brush (2 pcs).

-Disposable cups (minimum 4 pcs).

-Wood sticks (minimum 2 pcs).

- Butter, chocolate (150 grams).

-Exact scales (better jewelry).

-A little patience.

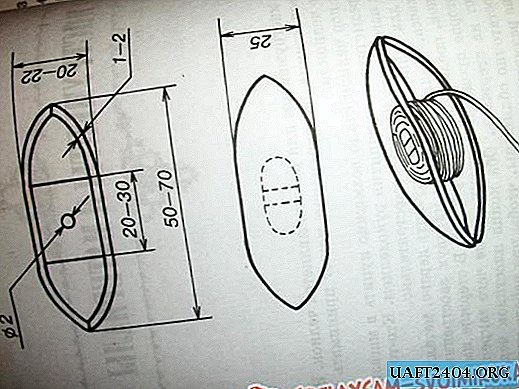

So let's get started. For starters, turn on your imagination and draw (preferably on paper, not in your mind) rough sketches of your future creation. The option to find a suitable image on the Internet is faster and the picture will be complete. Have you found? Take a bar of plasticine, knead it and (when your hands are no longer in pain) sculpt your Grandfather Frost.

Here is such a smiling "guy" turned out by the author. Now we need to take an imprint from the sculpture, so that we could pour chocolate. We take a board for modeling, put in the center of Santa Claus, and we sculpt around it the formwork all from the same clay.

Using the "sausage" method, we increase the walls according to the growth of the figure.

The resulting miracle is “stuck” with sheets of plasticine and rubbed well, leaving no cracks. Silicone has increased fluidity and even flows where not every microbe crawls. We pay special attention to the place of contact of our giant with the "mother board" - if it flows there, we will not be able to save the work. Now knead the compound.

In this case, it is food-grade silicone (we are looking in Google for the region of residence, because the compound presented in the work is unique and not for sale, but in parts the author “escapes” from the enterprise at the place of work). Option - Platinum23 (in the Ukrainian market it has sanitary and hygienic conclusions about the possibility of use for food products with a processing temperature not higher than 100 C). Silicone is translucent and consists of two parts - A and B. Mix according to the instructions (in example 1 to 1 by weight, not by volume). To assess the quality of mixing, dye is added to one of the components. The latter can be non-food in nature at the stage of replacing plasticine with plastic, and must be food when removing a copy from a plastic figure. After kneading, pour the resulting mass into the formwork and wait for the silicone to set. When instead of liquid in the formwork we find rubber, we release it from the shackles of plasticine.

The print is ready. With a knife, carefully, so as not to damage the plasticine model, cut the print. We see that the model is still damaged, we take a deep breath, put it aside and continue. Here is a print should be.

It is advisable not to cut it completely, but to leave any part connected - it will be easier to match the halves if necessary.

Next, mix the injection plastic. In the example, AcsonFast19 injection plastic was used. After kneading, we will have about 3-5 minutes to fill the liquid plastic that is still in the mold. Naturally, before that, the print should already be matched and bound with elastic bands (threads, scotch tape, etc.) into one. “Where to pour?” You ask. By comparing the halves, we will find that you can only pour in one place - in the feet where Grandfather stood at the stage of silicone molding. After pouring the plastic, close these openings with anything (pouring the rest of the silicone onto a smooth, clean surface and after hardening we will have an impromptu “plug”) and firmly, but gently press. You will need to keep it like this for about 5 minutes (to make it easier, the “plug” can be attached to the form). Open and remove the plastic copy.

It is rough and in some places may have the fingerprints of the sculptor (you can be found on them if you do something wrong and someone will be pleased with your creation). Therefore, with a sandpaper, carefully wipe off any bumps, defects, prints, etc. Polish plastic does not work. It will have to be coated with epoxy, which after solidification is completely inert and safe for humans. In the example, MagicKrystalFast jewelry resin was used. She will give Grandpa a gloss and eliminate all undercuts. The resin is mixed according to the instructions and applied with a thin layer with a brush. Having mixed everything according to the instructions and letting the resin harden, we create a new formwork.

Since chocolate is a fragile material, our shape should be more voluminous this time. The formwork is from the lining, glued with the same epoxy. The figure is screwed with a screw to one of the walls so that Santa Claus is in the thickness of the space and the silicone evenly envelops it. Next, repeat the molding step. Remember that the dye when mixing silicone at this stage should be only food. We get a silicone mold, but a larger size, respectively, a new formwork. We remove the plastic Santa Claus and lubricate the print from the inside with vegetable oil using a brush. Pour, like plastic, melted chocolate. After cooling, we remove Santa Claus.

Share

Pin

Tweet

Send

Share

Send